Novel heating concepts for electrical vehicles for extended drives ranges developed in DOMUS project

Intermediate result from partners IEE, CRF, Stellantis and HUT

Result has been achieved in December 2019 : month 26 of the project.

Short introduction

In future electrical vehicles concepts, radiant panel are discussed to play an important role to provide an efficient cabin heating. Efficient heating translates directly to an increase in the vehicle drive range. The key contribution of IEE to the DOMUS project are printing heating foils which will be integrated into interior components, such as door panels or lower dashboard parts, for the project demo vehicle.

This article is meant to briefly introduce IEE’s contribution to the H2020 DOMUS project and to provide the status of December 2019.

Objective

- The key contribution of IEE is the equipment of the demo vehicle with radiant panels for the interior components. IEE is a specialist for industrial manufacturing of printed electronics and supplies various printed sensing solutions for the automotive industry.

- The printing technique can be further developed to created thin and flat interior foils that are, due to their flatness and flexibility, easy to integrate into car interior components.

- Radiant panels are an integral part of future automotive heating systems. This approach can contribute to an increase in the drive range of electrical vehicles by saving considerable heating loss. IEE aims to provide the means to assess these heating savings in theoretical studies as well as real life testing. This will be realised by developing interior heating foils for the DOMUS demo vehicle, a FIAT e500, and by related technical input in the simulation studies for the project.

Research

During the project, a proposal was made on how to equip the demo vehicle with panel heaters by translating the objectives of the project into technical requirements for the heating concept. The proposal is further based on vehicle comfort simulations and testing results, with the vision to surround passengers by heated surfaces.

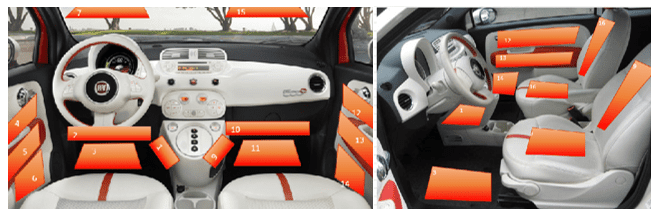

It is planned that the radiant panels deliver in total about 2KW heating power to the cabin, which allows a significant contribution to the total heating power required even in demanding use cases and test scenarios. The image below shows the intended positions of the first seating row in the demo vehicle (FIAT e500). In total, it is planned to make use of up to 24 heating areas covering all passenger seats.

Image: Planned positions of the radiant panels in the demo vehicle

The radiant panel concept foresees that the panels can be individually controlled with a temperature set-point specific for each surface. This is important as the temperatures of the panels, and thus the provided heating power, depend on environmental variables, e.g. ambient temperature or wind speed, as well as the personal comfort preferences of the passengers. To bring the system to life, a control unit was designed to allow the integration of the radiant panels into the electrical and logical system architecture of the demo vehicle.

The heating foil samples will be designed and made in a parallel manner to cope with the project timing. The following chapter describes the status in Dec 2019.

Result

The heating foils must fit very well into the complex surfaces of the interior components and needs an advanced design approach to match the requirements of the application. Obviously, the heating foils must be integrated in a way that the interior design is not affected (or only to a low degree) to achieve a high market acceptance of the technology. This can only be achieved by integrating the heating layer below the top décor surfaces or at the backside of the interior components.

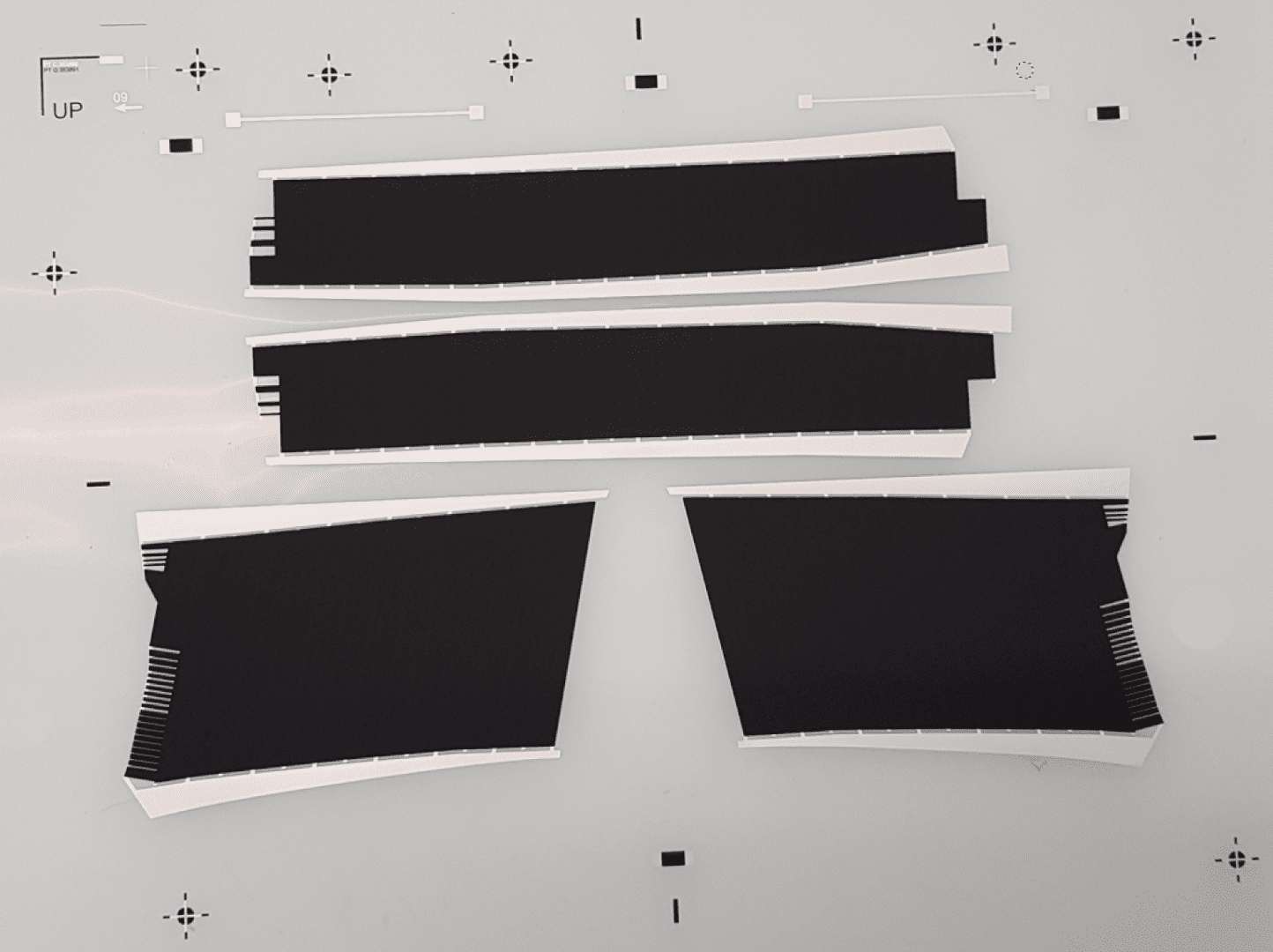

The challenge of the project is that each heating position represents a specific and complex surface shape with various thermal boundary conditions with respect to thermal insulation and heat capacity. Thus, each surface requires a specific heating foil design with specific heating power ratings. This requires interactive collaboration within the consortium to manage available space constrains and technical interfaces, for instance. The image below shows the result of the foil shape fitting studies of the rear quarter back panels as an example. The design process for the heating panels is ongoing, most of the positions are addressed. The image below shows the backside of the rear quarter back panel with the result of the foil fitting procedure.

Image: backside of rear quarter back panel showing the result (white templates) of the heating foil shape definition process

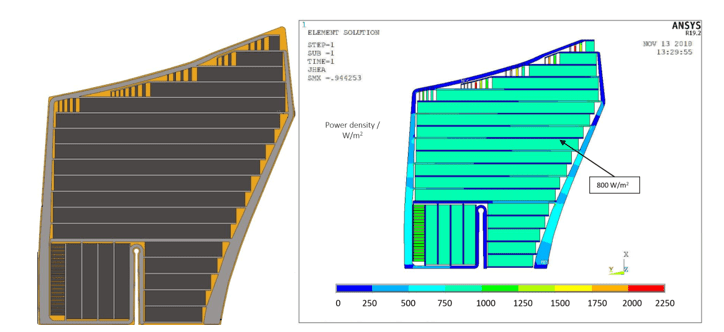

As each heating position has its own shape and power rating the functional structures also need a specific design. As the definition of the print foil requires a set of design boundaries, a design method was developed. Each heating design is finally validated with a finite element method to ensure a heating power distribution as required.

Image: Design CAD model and power density simulation to validate design

The manufacturing of the heating foils has been initiated and the first parts are ready. The missing ones are set to be ready for the demo vehicle build starting in April 2020. The following chapters provide insights into the status of December 2020 with respect to component integration and control unit development.

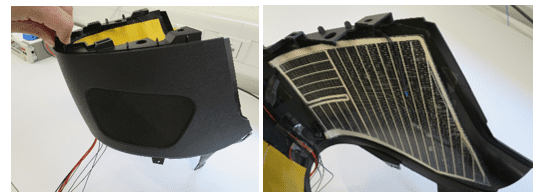

The functional structures of the heating foils are prepared by screen printing. The application requires highly specific materials, polymer substrates and printing inks. The image below shows an example of the print for the lower front door panel heaters.

Image: Example of a printed heating foil for the DOMUS demo vehicle, here lower front door panels heaters are shown

The heaters will be integrated in the top decor layer at the backside of the interior components. The image below shows the central console with a heating layer integrated at the backside. The heater will be covered at the backside with an insulation layer to focus the heat flow to the front site.

Image: Central console of the DOMUS demo vehicle with integrated printed foil heater (insulation layer not shown)

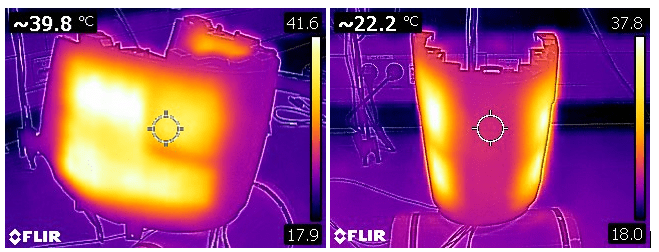

The interior components will be validated and tested to ensure a conformal heating performance for the demo vehicle. The image below shows a thermography of the central console with heaters running at a target temperature of 40°C.

Image: Infrared images of the DOMUS test vehicle central console

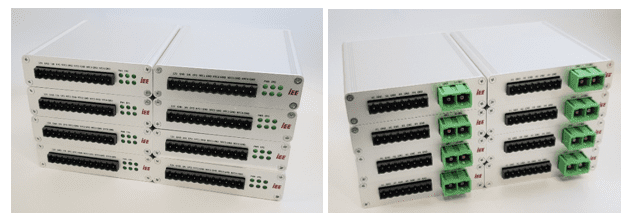

The demo vehicle, and further serial cars will need an advanced approach to control the plurality of the heater. Nowadays, the heating, ventilation and air conditioning typically work with a single central control unit. However, with multiple interior heaters distributed in the whole cabin, such an approach would lead to a significant wiring effort, adding weight to the vehicle. Additional weight conflicts might interfere with the goal of saving energy to extend drive range. One viable solution would be to control interior heating with distributed control units.

Such a concept will follow for the DOMUS demo vehicle as well. Thus, control unit have been developed to provide the technical capability to run the heater in the vehicle and to provide a proof-of-concept for the selected approach. Each unit features four control channels with a closed loop temperature controller. The unit can be controlled via LIN communication. In the demo vehicle the central HVAC unit will take control over the radiant panels target temperature settings.

Image: Image of radiant panel control units for DOMUS demo vehicle for proof-of-concept studies

What will the results be used for?

The interior components equipped with heating layers and the control units will be used to effectively build a demo vehicle with the aim to prove the energy saving potential of the novel heating approach. The heating designs are also introduced in the comfort and energy simulation framework of the consortium to access the performance by theoretical means.

What is the impact?

The project’s goal is to develop and validate measures that jointly extend the drive range of the vehicle for a storage capacity of the battery. Beside the energy for driving, the heating of the cabin is one major factor in the energy balance of the vehicle. Consequently, saving heating energy increases the energy of the battery package that can be used for driving.

IEE’s contribution allows for the assessment of the energy savings thanks to the new approach of using radiant panels as integral part of cabin heating systems.